Quality Control is an integral element of our process when producing adhesive tape products here at Pro Tapes®. Today, we have a chat with Chris Klostreich, our Quality Control Manager, to learn more about the Quality Control philosophy behind your favorite products from Pro Tapes®.

Peek Behind the Scenes into the Quality Control Lab

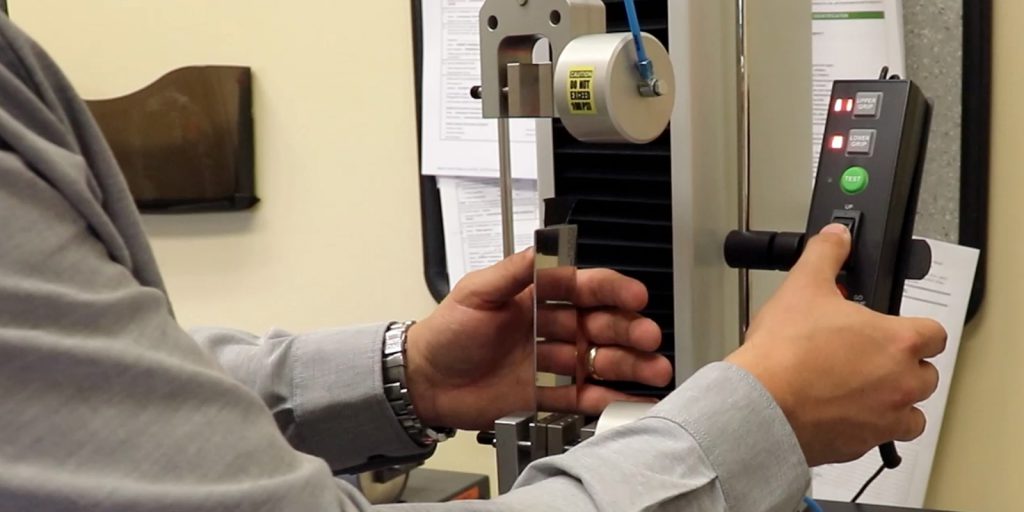

With Chris’s help, we also filmed a Behind the Scenes video of the QC Lab, so you can get a peek into some of the processes and tests we run on a daily basis. Check it out:

Hey Chris, thanks for talking with us today! Tell us a little about yourself, first.

Hey there! I am a Quality Control professional with more than ten years of experience in the manufacturing industry. Despite a few industry and job changes over the years, “quality†seems to have ultimately “stuck†with me (tape pun intended!)

I believe “quality†found me during my undergraduate business history studies of Henry Ford and J. P. Morgan and while learning about modern enterprise business systems. I went on to study and seek certification within Integrated Lean Six Sigma (IL6S.)

What do Quality Control (QC) and Quality Assurance (QA) mean to you?

Quality is a developing theory through modern descriptive business systems. Formally, “quality control†is typically regarded as the validation and qualification of physical items produced through the manufacturing process.

Whereas “quality assurance†is the qualification of the process itself; leveraging risks and evaluating possible outcomes. It is often “end-to-end,†encompassing suppliers/vendors, internal functions, external requirements, and customer demands.

I think of quality control as a “business philosophy†(a la Deming, Crosby, Juran, and other great titans of industry.) I believe the IL6S philosophies hold true across the span of the manufacturing industry, no matter how simple or complex the finished product is.

To me, “quality†means synthesizing a learned understanding from various business minds and attuning this knowledge to the company’s internal culture, brand reputation, and actionable plans for continued improvement.

This helps us focus beyond the trajectory or ‘desired/future state’ of the company, through to the bottom-line actuals that make up the future. It may seem a bit dreamy, but that’s my perspective.

Identifying and filling execution gaps (DMAIC), managing programs and projects via QA process tools, and executing opportunities for improvement are much more difficult in reality than I may describe them to be!

But quality tools like these assist us in being the architects of our own success.

What does Quality Control look like at Pro Tapes® specifically, and why?

At Pro Tapes®, Quality “management†encompasses the activities of both QC and QA, with the inclusion of modern business systems thinking, and the philosophical approach I described earlier.

We define a forward-thinking, positive future-state, in order to identify risks, opportunities for improvement, and to discover how to “close the gap†between our current-state and our desired-state.

This knowledge is used to generate positive outcomes externally (timely and desired product to market delivery, profitability, end-user satisfaction) and internally (employee engagement, systems implementation.)

With the help of our program and project management systems, we can produce repeatable outcomes, bring uniform, high quality products to market, and exceed yesterday’s vision of the future, as a team.

Are there any standards we “stick†to when manufacturing and QC testing our adhesive tape products?

We follow the Pressure Sensitive Tape Council (PSTC, www.pstc.org) standards for substantiating test data, i.e. defining characteristics of the adhesive tapes we manufacture. The PSTC is a trusted standard for more than sixty years and counting!

The PSTC standard is fairly commonly cited within the PSA (pressure sensitive adhesive) industry, and accompanies ASTM, MIL specs, UL and other third-party standards and certifications.

The North American trade association for tape manufacturers, which established and updates the PSTC, has a global fingerprint spanning beyond North America.

Does Pro Tapes® have any other special certifications for Quality Control?

Pro Tapes & Specialties® is a 9001:2015 certified company. We are not ISO/IEC 17025, or otherwise “lab certified,†but we keep up with modern technology brands like Thwing-Albert, ChemInstruments, etc. to keep our capabilities accurate, repeatable, and recorded for accuracy, and reliability.

Thanks for sharing that with us Chris! Share one more fun fact with us: What’s YOUR favorite Pro Tapes® product?

It’s a toss-up between UGlu® and Pro® Artist Tape for my favorite Pro Tapes® product!

UGlu® is awesome for its functionality and universal applications (product and point of sale display assembly, party décor, so much more), but Pro® Artist Tape is also great for the savviness and range of colors it provides for craft projects.

Brake Disc

Brake Disc,Car Brake Disc,Automobile Brake Disc,Auto Brake Disc

Zhoushan Shenying Filter Manufacture Co., Ltd. , https://www.renkenfilter.com